Salt Spray Chamber: Ensuring Corrosion Resistance with Precision Testing

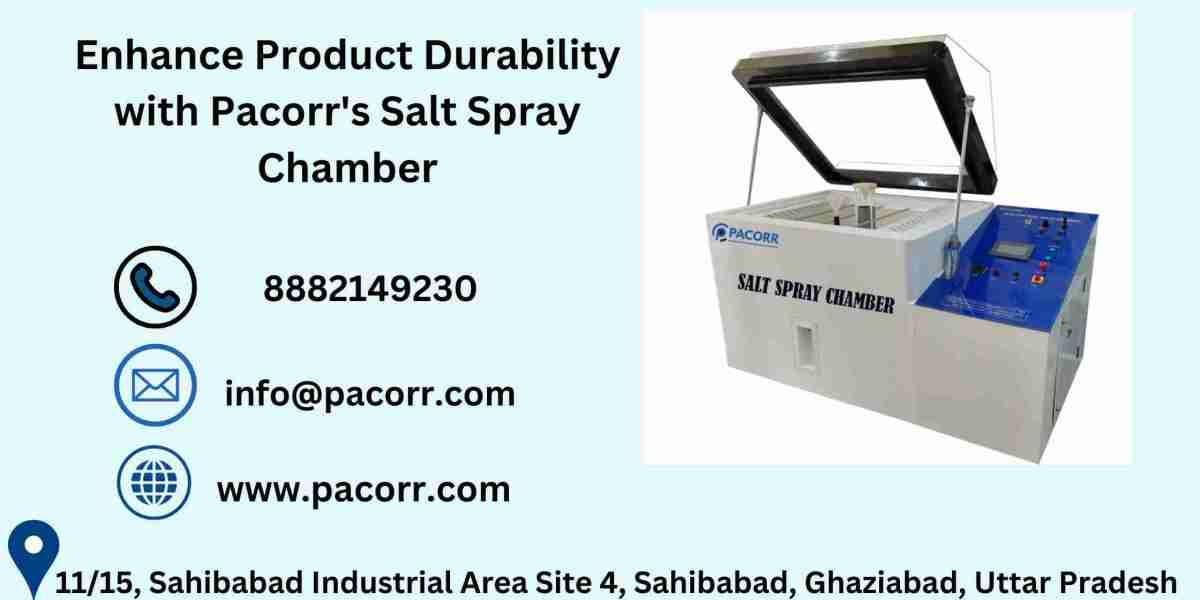

In industries where metal components play a vital role, corrosion is a significant challenge. It can compromise the structural integrity, appearance, and lifespan of materials. To mitigate these risks, accurate testing methods are essential. Pacorr’s Salt Spray Chamber is a state-of-the-art solution that ensures thorough and reliable corrosion resistance testing, helping manufacturers maintain product quality and durability.

What is a Salt Spray Chamber?

A Salt Spray Chamber, also known as a salt fog chamber, is a testing instrument designed to simulate corrosive environments. It subjects samples to a controlled saline mist, replicating real-world exposure to saltwater or saline atmospheres. This allows industries to evaluate the corrosion resistance of metals, coatings, and surface treatments effectively.

Pacorr’s Salt Spray Test Chamber is built to meet stringent testing standards, making it a preferred choice across automotive, aerospace, electronics, and construction industries.

Features of Pacorr’s Salt Spray Chamber

- Precise Testing Environment:

The chamber provides an accurate saline mist environment, ensuring consistent test conditions for reliable results. - Durable Construction:

Made with high-quality, corrosion-resistant materials, the chamber ensures long-term performance and minimal maintenance. - User-Friendly Interface:

An intuitive control panel makes it easy to set test parameters, monitor conditions, and retrieve data. - Compliance with Standards:

Pacorr’s Salt Spray Chamber adheres to international testing standards like ASTM B117, ISO 9227, and JIS Z 2371, ensuring global compatibility. - Customizable Test Cycles:

Users can adjust temperature, humidity, and mist intensity to suit specific testing requirements.

Benefits of Using Pacorr’s Salt Spray Chamber

- Improved Product Quality:

Identify potential weaknesses in materials and coatings before they reach the market. - Enhanced Durability:

Ensure that products withstand harsh environmental conditions, boosting customer satisfaction. - Cost Efficiency:

Minimize recalls and replacements by addressing corrosion issues during the product development phase. - Compliance Assurance:

Meet industry-specific quality standards to maintain certifications and market credibility.

Applications of the Salt Spray Chamber

- Automotive Industry:

Testing the corrosion resistance of vehicle parts, such as engine components, exhaust systems, and chassis. - Aerospace Sector:

Evaluating the durability of aircraft components exposed to extreme environments. - Electronics Manufacturing:

Ensuring the reliability of metal casings and connectors against corrosion. - Construction Materials:

Assessing the longevity of metal structures, fasteners, and protective coatings.

Why Choose Pacorr’s Salt Spray Chamber?

At Pacorr, we prioritize precision, reliability, and customer satisfaction. Our Salt Spray Chambers Price is engineered to provide unmatched performance, enabling manufacturers to protect their products and brand reputation. Additionally, our team offers robust support and training to help you maximize the efficiency of your testing processes.

Final Thoughts

Corrosion testing is a cornerstone of quality assurance in industries reliant on metal components. Pacorr’s Salt Spray Chamber is a trusted solution to ensure your products stand the test of time in harsh environments. With advanced features, compliance with global standards, and versatile applications, our chamber is an investment in reliability and durability.